The lye solution triggers a chemical reaction that turns the oils of a soap recipe into solid soap. When you first start making cold process soap color choices can be really overwhelming.

Cold Process Soap Lye Water Solution Coloring Pages - If you're searching for video and picture information linked to the key word you've come to visit the ideal site. Our website gives you suggestions for seeing the highest quality video and image content, hunt and find more informative video content and images that fit your interests. includes one of tens of thousands of movie collections from several sources, especially Youtube, therefore we recommend this video for you to see. It is also possible to contribute to supporting this website by sharing videos and images that you enjoy on this site on your social media accounts like Facebook and Instagram or educate your closest friends share your experiences concerning the ease of access to downloads and the information you get on this website. This site is for them to stop by this website.

Cold Process Soap Making Tutorial

Weve crafted a complete guide to cold process soap with a basic recipe step-by-step instructions and some trouble shooting tips to help you make your cold process soap batch.

Cold process soap lye water solution coloring pages. These molds behave similarly to silicone molds but are even worse at holding onto cold process soap. Water - 2432 Lye - 88 ozs Coconut oil - 128 ozs Olive oil - 448 ozs Palm oil - 64 ozs Total oils - 64 ozs. The cooking process will help get rid of excess moisture and will complete the saponification process.

These are simply pigment in melt and pour soap and. The first step when making cold process soap is making the lye-water mixture that is needed. Soap can be made with a higher percentage solution 50 - equal parts water and lye but it is more difficult and is considered and advanced technique.

So maybe this little extra water and this little lack of lye could explain the softness. Today is the next lesson in the Back to Basics Cold Process Series. When the lye water has reached a temperature of between 100-110 degrees F and your oils have reached a temperature of between 90-110 degrees F you are ready to pour the lye water into the bowl containing the oils.

If you want harder soap next time up the amount of hard oils gel the soap and keep the liquid amount to a maximum of 40. Pros of water discounting. However while you are working with the lye solution you must do so carefully and take safety.

This will color the water which will add color to the soap without the extra powdersspeckles. Add the clay to the lye water and make your soap. 30 to 50 grams of your favorite essential oils or fragrance oils you will need a bottle of 30 to 60 milliIitres the equivalent of 1.

I also made the INS calculations the value is 15809. Learn to Prepare Colorants for Cold Process Soapmaking from Soap Queen on Vimeo. Its the perfect recipe for the beginner soaper.

Beginner video showing how I mix lye in water for soap making. If you have suggestions for improvement or more warnings that need to be added please comment. Use sodium lactate or salt in the lye solution a water discount and a high amount of solid fats.

We also have a battery powered 4-in-1 Mini Mixer that will make the job fast and easy. If the problem is not enough lye it can be difficult to fix since it is unlikely you know how much lye you need to add. Today we are reviewing how temperature affects cold process soaping.

As the soap cures the water evaporates and creates harder longer-lasting bars. I wanted to create this guide to help break down the colorants for cold process soap and help you learn how to use them. The other option is to make an infusiontea in the water portion of the soap making process.

N Cold process soap has a high pH. Typically a recipe uses about 22 liquid. Please note this recipe will make a soap with very little bubbles.

77 grams lye sodium hydroxide 228 grams distilled water. In all the books and information I have found on Cold Process soaps it says that 30-35 of water should be used. Peppermint Mentha piperita.

You can discount that to make a more concentrated lye solution. Herbs and spices for coloring CP Cold Process and HP Hot Process soap. Hand in making your cold process soap.

Water is used to dissolve sodium hydroxide lye so it can react with the oils and start the saponification process. N Soap Color Bars - Some suppliers also sell pigment color bars. However you can also add it to the lye solution before mixing with the oils to the finished cooked soap or right before mixing to trace.

Dont do this until you are ready to proceed with making soap from scratch. For more information on coloring your soap. If the lye water temperature is too high you can place the pitcher in a bowl or sink of cold water to cool it.

To the oils before pouring in the lye solution. This link will take you to a great list of our pigments and below you will see some of our best lightweight oils for mixing colorants. And in that process the lyewhich is a caustic chemical that can burn skin and eyes as well as be harmful when inhaledbecomes neutralized.

Red Moroccan Clay Red Kaolin Clay. Use 12 tsp to 15tsp per pound of soaping oils to get a chocolately brown colour. Another thing 340g of water represents more than 37 of the quantity of oils.

If you missed yesterdays Basic and Simple Cold Process Soap be sure to check it out. Additive and scent at light trace. N If you are making a swirled soap you can add each color to.

How to Make a Wood Loaf Soap Mold Learn how to make a loaf wooden soap mold that yields 10-12 bars as well as where to source lye and how to line a wooden soap mold. Even then clear plastic molds arent always reliable. Tomorrow will feature another cold process tutorial including.

Lye Water Solution. Lye is a caustic dangerous chemical that can cause serious burns but you can work with it safely if you take a few precautions and understand basic soap making safety procedures. Beige to beige with dark specks if the leaves are left in - Infuse leaves in waterlye solution.

Likewise soap can be made with a lower percentage solution 25 - three times the amount of water than of lye but it takes a long time to make and is generally reserved tricky multi-color soaps that need plenty of time during which they can. If you are just getting started in coloring and swirling your soap I.

Back To Basics Simple Gentle Cold Process Soap Soap Queen

Back To Basics Layered Lavender Cold Process Tutorial Soap Queen

Pin On Soap

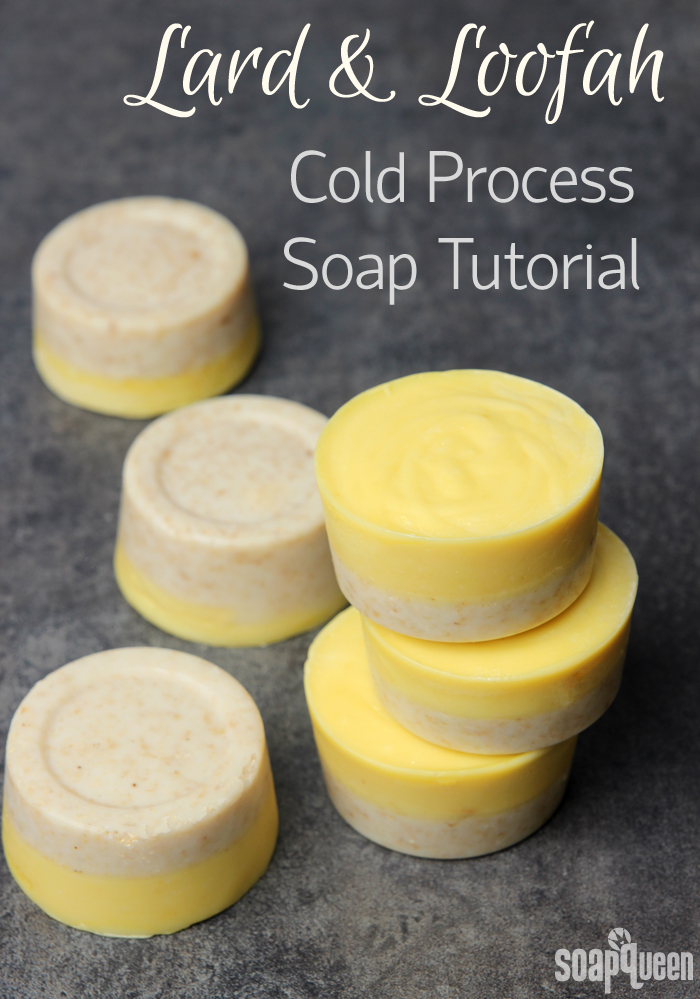

Lard Loofah Cold Process Soap Tutorial Soap Queen

Pin On Soap

Milk And Honey Soap Cold Process Vs Hot Process

Pin On Soap Stuff

Pin On Zero Waste Beauty

My Favorite Cold Process Recipes Soap Queen